At last year's Homebuilding Show at the NEC, I gave a short presentation on how to ensure success when designing and installing a natural stone project. I'll be giving a more in-depth talk on Thursday 9th Feb 2017 at this year's Surface Design Show #SDS17.

The SDS show is specifically for designers and architects. Let me know if you would like complimentary tickets.

*************************************************************

The Homebuilding and Renovating Show, NEC 2016:

Another busy Homebuilding and Renovating Show at the NEC has just come to a close. This year, we focussed on our unique range of French limestone and a small selection of eye-catching Portuguese marble.

At this year's show, I was "volunteered" by my wife and daughters to give a seminar on the "Selection and Installation of Natural Stone". So, the audience got to hear a cut-down version of the presentation that I give to the Stone Federation at their regular training events. In the seminar, we discuss the importance of selecting the correct stone for the project and we run through the key elements of installation.

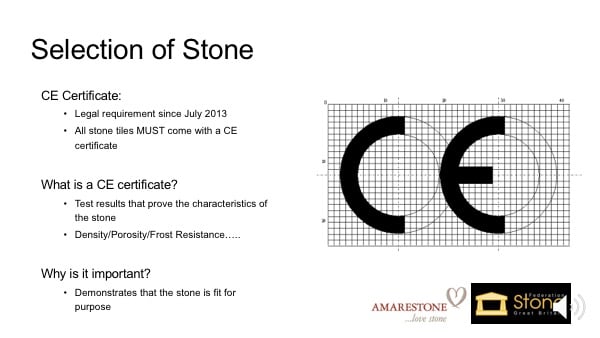

For example, did you know that all natural stone tiles sold within the EU must have a CE certificate? In this presentation, we explain why this is a good thing and not simply an example of EU bureaucracy.

Did you also know that plywood and plasterboard are very poor substrates for tiled surfaces?

The slideshow will give you a brief explanation of the reasoning behind this. I hope you find it useful.

A few examples of where natural stone can be used in and around the home:

The key thing to look for when choosing stone is the CE certificate. Without one, importers, architects, designers and specifiers will be breaking the law.

But without one, how will you know for certain that the stone will be fit for purpose and do the job you need it to do?

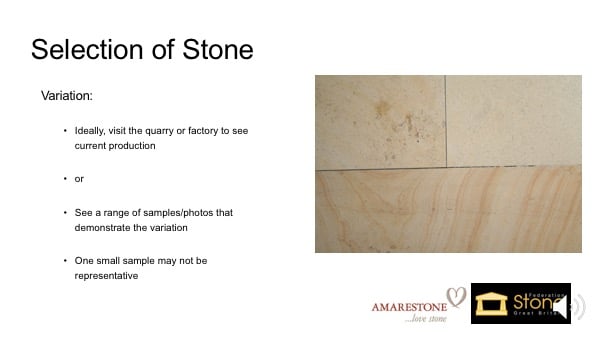

The three tiles in the image above are all from the same batch and were all cut from the same block of French limestone. One small sample from any of these three tiles could be very misleading if that's all you have seen in order to choose your new flooring. Make sure you know what degree of variation is likely before you confirm order. The quarries will often provide photos of the latest production to your supplier, so you just have to ask.

Don't leave yourself short! At best, it will cause delays to your project and potentially, the top-up order could be from a very different batch to the original and look out of place when finally installed.

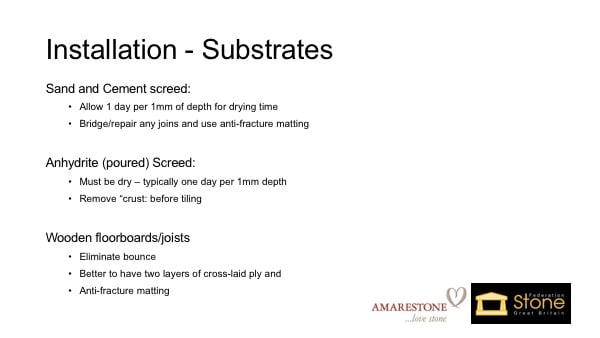

Anhydrite (poured) screeds are fantastic because they give you a nice flat surface for tiling but ensure they get the full drying time of 1 day for every 1 millimetre of depth. The laitence (or "crust") forms as it dries and this has to be scraped off before the anti-fracture matting or tiles are laid. The laitence is like a crust that forms on the surface and it eventually flakes off. So, if it is not removed, anything stuck on top it will also come loose after a few months.

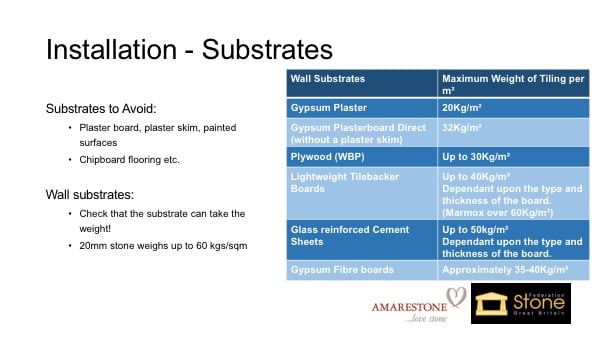

The key message from this slide is "don't tile onto plasterboard or plywood". Not only because they can't take the weight of the tiles but also because plasterboard and plywood swell if/when they get. Worse still, plywood can leach colour from the wood dye into a stone tile.

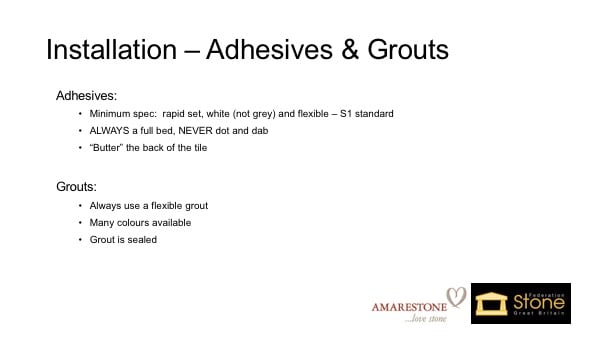

Please don't cut corners by using cheap ancillaries. Our preferred brand is Mapei but there are other premium brands. Look for "S1" flexible, polymer modified adhesives to ensure you get the best possible bond between tile and substrate. And always use white and not grey with natural stone.

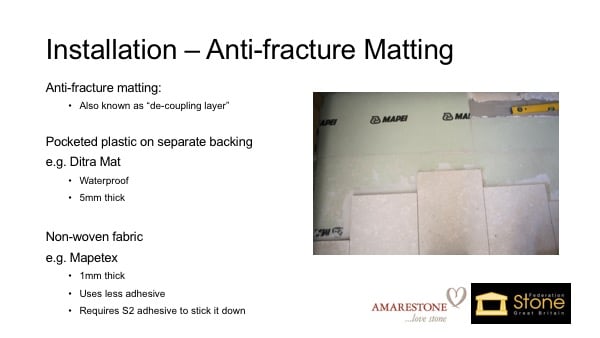

As I was getting set up for my presentation, the Show seminar manager chatted to me and said, "You will talk about anti-fracture mats, won't you? There are so important to help avoid cracks and I made that mistake once before!"

He's quite right. In my view, they should be specified for any type of tile installation, whether stone, porcelain or ceramic, particularly where there is underfloor heating and DEFINITELY where two different substrates meet.

This is a simple process but it's so important to follow it carefully. It is essential to use a ph neutral detergent to wash the polymers from the adhesives and grouts off the surface of the stone to get the best results.

At the risk of repeating myself, always use an anti-fracture mat to reduce the risk of cracking from thermal expansion and contraction from underfloor heating systems. Check that the system works before starting the tiling. Once tiling is complete, leave the system switched off for a couple of weeks to allow all the moisture from the adhesives to dry out. Once dry, raise the temperature by no more than 2 degrees per day until the required temperature is reached. This will help to prevent the risk of cracking from "thermal shock". Once the system has been brought up to full temperature, it can be operated as normal thereafter.

My advice would be to choose an impregnator sealer - one that is absorbed into the stone. Topical (surface) sealers similar to varnishes wear away and leave the stone unprotected. Water based impregnator sealers are getting better but top quality solvent based sealers will last longer. However, solvent based sealers are only effective if the stone is allowed to dry to fully before being applied. The job of the sealer is to repel moisture. But, if there is moisture present in the stone, the moisture will actually repel the sealer and prevent it from being absorbed by the stone. It will simply sit on the surface and evaporate away.

You can prolong the life of the sealer by using a cleaner which will work in harmony with the sealer. Therefore, it makes sense to use the cleaners that the sealer company makes as they will have been tested together. Our preferred brand is Fila, the Italian company. The Italians have a long history of working with natural stone and they do seem to know what they are doing. We have been using them in our projects for more than 10 years now. Be wary of using the cleaners that you might find in the supermarket as they usually contain either bleach or acid and may damage the stone as well as degrade the sealer and shorten its life.

If you have any questions, please raise them by filling in the comments form below. It's quite likely that others will have similar questions and it might be helpful to have them answered here.

I'm always happy to get phone calls or emails but you can also look for Amarestone on Facebook or Twitter and post your questions there.

*************************************

If you are planning a natural stone project and would like to discuss some ideas, give us a call or get in touch by email (my contact details are below).

Our brochure explains how we work and how we can help your natural stone project be successful.

Thanks for reading.

Steve Turner

Amarestone

Tel: 0345 260 8070

Email: steve@amarestone.com

P.S. - get the next blog direct to your inbox by entering your email address in the box on this page.